How to Avoid EPA Fines and Penalties

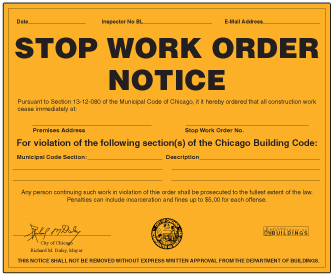

You can’t manage what you can’t see. Poorly Managed Environmental Inspections, Action Items, Documents, and Maps = HEAVY FINES & PENALTIES

Where are your Stormwater or SPCC Plan inspections? Do you have instant access to them so that you can see if they are even being done? Do reports contain open and closed action items by dates? Are these plans accessible to anyone that needs to view them? Do they contain current regulations, permits, proper certifications, or other necessary items? Are specific components like maps and specifications being properly updated?

What is a SWPPP?

These are questions that industry professionals are presently considering as a growing emphasis is placed on environmental compliance and enforcement in our communities nationwide. Ready-mix batch plants and other related concrete production facilities take no exception to this.

For example, most plants and production facilities have to manage a Spill Prevention Control and Countermeasure (SPCC) plan due to the qualifying amount of fuel, oils, and other petroleum-related products used on site. As well, a Stormwater Pollution Prevention Plan is required by the Federal Clean Water Act on most concrete production facilities that have exposures to rain or snowmelt. Federal, state, and or local regulations are very specific when it comes to how these plans are managed. After all, these plans become the “court documents” in the case of a regulatory review, derived of self-monitoring documentation that is required by their complicated regulations. As inspection and documentation demands within these regulations grow more complex, coupled with both ever-increasing regulatory oversight and social consciousness of environmental concerns that have everyone under the microscope, companies are desperately trying to solve how to best meet them to stay compliant and avoid the negative publicity, costly fines and penalties that are on the rise. All of this, while trying to build profits. Does this current state of affairs not beg the simple question of how and what to do?

So, what is the best way to efficiently manage these plans legally with their ongoing inspections, documentation, and reporting?

While many environmental regulations can seem burdensome, the regulations also allow some common-sense methods for achieving compliance. One such method allows technology to be implemented to perform inspections with electronic signatures, create and communicate action items, electronically update maps, and the overall electronic management of all environmental documentation, management, and communication. Company management personnel have been trying to figure out the best way to perform and manage components within these regulations on site for quite some time. Mailboxes, lockboxes, spreadsheets, handwritten checklists/notes, and other methods have been painstakingly used to try and meet these regulations. However, as you can imagine, inspections are often missed, action items are not noted or communicated, and maps/plans commonly go unkept. In some instances, these federal documents are even lost, vandalized, stolen, mismanaged, weathered, and ultimately not compliant. Company management personnel often struggle when emphasizing the need for continual upkeep and management of the SWPPP and SPCC, especially if the only way to see if plans are being managed and inspections are being performed is to actually drive to the site to view what is going on! When this is the case, compliance accountability, due to the lack of accessibility and verification, takes a dive while liability risk skyrockets; thus becoming a major problem for any company, let alone companies with multiple regulated facilities and operations. And, it appears that the federal government is ready to require states and local municipalities to manage programs like the NPDES (National Pollutant Discharge Elimination System – Federal Clean Water act) electronically. This would certainly encourage anyone wanting to comply to utilize technology to save everyone money and time in the process.

Online software that will enable companies to perform inspections, document action items, update maps and other documents while managing it all electronically is more sustainable and provides a much better way to manage an environmental program more efficiently and make it compliant. This concept is the very beneficial essence of implementing technology. As long as the way to electronically access updated plans, completed inspections, action items, and documents are posted with the permit, your site is complying with the law. The benefits of utilizing technology for electronic management are obvious. Never has there been more incentive for the implementation of technology to enhance operational processes than in this day and age where everyone has a smartphone, tablet, or access to a laptop or computer. Three ring binders and hard copies of the plans, inspections, and all that other stuff are a thing of the past. Electronic performance and management of all things environmental is the process of the future, no different than our online banking accounts or filing our taxes electronically. This increases profitability provides more flexibility and drives improved compliance.

Consider these advantages when utilizing technology to manage your environmental program

That being said, the real reason you need a SWPPP is to ensure that everyone working on your site is on the same page about how you will protect the water bodies that receive stormwater runoff from your site.

- The correct inspection forms for each permit so it can be utilized, managed, and amended

- Inspections and management on any device – a paperless process – saves time and cost

- The correct inspection frequencies for each permit

- Adaptable inspection forms in real-time when changes need to occur

- Directives on inspection forms and action prompts can help ground operations comply

- Action items you can drive electronically for communication and completion

- Keymaps/drawings, etc. that are easy to create, amend, and update

- Platforms for all compliance documents-readable, accessible, retainable

- Training modules are available 24-7 – operators access them when convenient for them

- Reports you can run for quality control and employee evaluations

- Action items you can quantify by open and closed dates

- Key reports you can run to properly manage this cycle

- Non-compliance communication gaps from ground operations to management are closed

- “The eye in the sky” – you can’t properly manage what you can’t see

- Company protection and personal risk management – close compliance gaps in any program